29.06.2022

29.06.2022

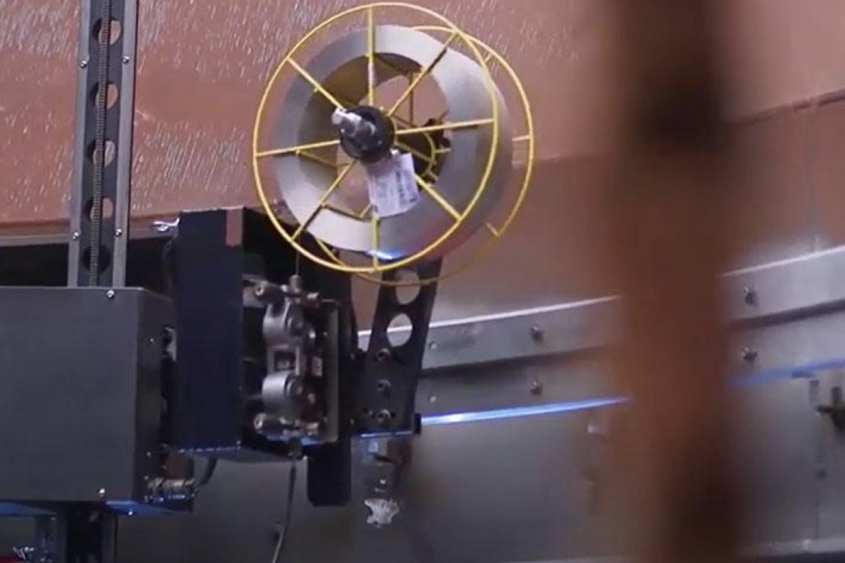

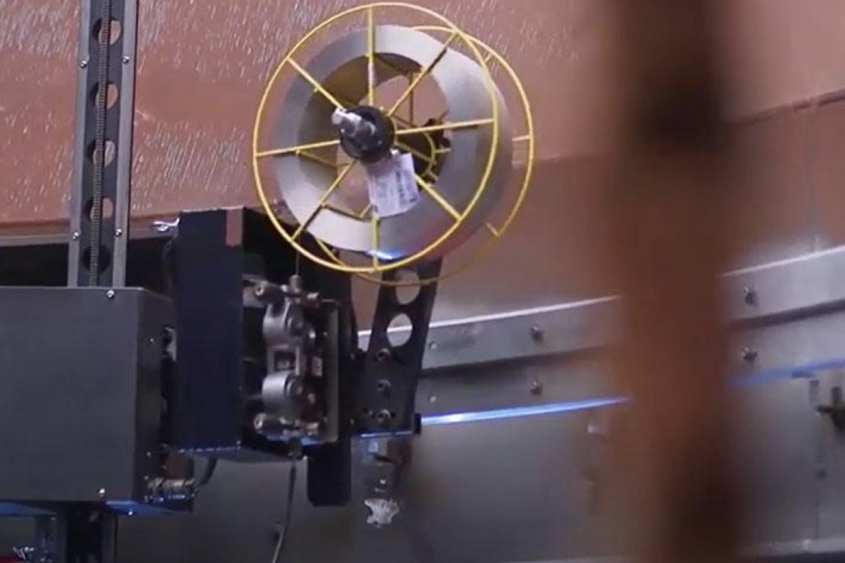

SULZER has chosen for its high-end CladFuse™ system a swissmade MEFRS 2044-37 wire feeder from Mechafin AG. We say a perfect match!

Sulzer CladFuse™

As a leading provider of specialised field service, Sulzer is a global expert in equipment retrofitting and maintenance. With more than 40 years of experience in the column,drum and vessel industry, they guarantee their customers safe, cost-effective and technically proficient work.

Using automated welding equipment, Sulzer teams can repair cracks and dents in the vessel shell, rebuild corroded or eroded areas, restore adequate material thickness and, using quenching and tempering layer technology to improve metallurgy.

The advanced automatic welding equipment CladFuseTM developed by Sulzer enables high-quality welding. In addition, Sulzer has extensive experience in replacing vessel heads, shell sections and frames. Field service teams can repair corroded or eroded vessel shell nozzles by reworking the worn areas, restoring the allowable thickness, using an advanced metallurgical process that employs annealing layer technology.

With CladFuse™, Sulzer offers you a high-quality product

- Advanced automated welding equipment

- MSG and TIG pulse welding processes

- Controllable and minimal segregation, <10%.

- Precise control of parameters to achieve high quality build-up welds

- Optimised material thickness application

- High operating speed to reduce downtime

Source: Sulzer

Click here for more information: